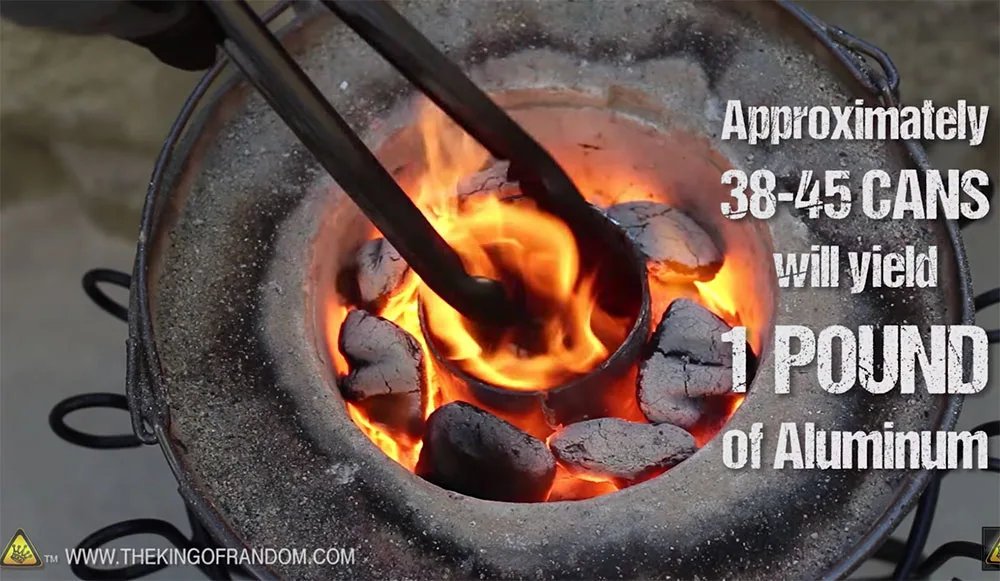

Let’s melt some metal! The King Of Random has done it again by building a homemade mini metal foundry with a steel crucible. It will melt aluminum cans with over 1000 degrees of heat provided by regular old charcoal and a hair dryer.

Grant Thompson decided to build a homemade metal foundry from a mixture of 50% plaster of paris and 50% play sand.

The King of Random | YouTube

The plaster and sand are a good insulator and focus the heat in one central area. Airflow is controlled by a simple $3 hair dryer from the dollar store and results in positive airflow into the heart of the crucible. This raises the heat exponentially – much like a rocket stove – using very little fuel.

The King of Random | YouTube

This is the coolest, amazingly practical homemade metal foundry. With a price tag of only $20, it’s much more affordable than the expensive manufactured models out there.

Safety is an issue, and Grant makes sure this is clear. This is a metal foundry and it gets HOT HOT HOT! There is the danger of getting severe burns if not handled properly.

It is probably a good idea to get a real crucible that’s designed for melting metals, and as Grant describes you can get one for about $30. This is well worth the money for safety reasons.

The King of Random | YouTube

There are loads of off grid and homesteading uses for a homemade metal foundry like this. You can make all sorts of practical items if you’re familiar with how to make and use molds and castings.

“I ended up favoring the galvanized steel pail, and a mix of 50% plaster of paris, and 50% play sand, by volume, which was inspired by a video by NightHawkInLight “How to Make a Soup Can Forge” http://bit.ly/IBSoupCanForge

Depending on where you get, or find, your materials the cost can range anywhere from $5-$25 per unit. With the materials I used, I was able to make 2 units for under $40 ($20 each). Even on the high end, this is probably one of the cheapest, reliable, backyard foundries that can be made.

The King of Random | YouTube

The purpose of my backyard foundry is to demonstrate the most basic setup for casting metals. However if you plan to attempt this approach yourself, some important things to consider beforehand are as follows;

– Soda cans work really well, however aluminum cans are one of the worst sources for aluminum to cast with, and some soda cans in the UK are actually made of steel. The alloy was meant for extrusion, so is not the best for casting. They also produce more dross (slag) because the thin walls oxidize quickly and the plastic coatings on the cans add impurities. A better source of aluminum for casting would be cast aluminum items from thrift stores, like electric skillets or small engine blocks from lawnmower shops.

The King of Random | YouTube

– The crucible I used was steel, but it’s important to note that steel can be soluble in molten aluminum. It’s possible that when you lift the crucible out of the foundry, the bottom can dissolve out and drop molten aluminum onto you feet and onto the ground. A good refractory crucible can be purchased for about $30 online.

The King of Random | YouTube

– Lastly, casting over concrete poses risks of steam explosions. If molten aluminum falls to the ground, it can superheat the moisture in the concrete and cause it to spall (steam explosion) where the aluminum lands. This can potentially send hot concrete and molten aluminum spraying everywhere. When possible, melt and pour metal over sand to minimize risks.

The King of Random | YouTube

Note: Wearing polyester gloves like the ones I had in the video is risky because the material can melt into your hands if you get splashed by hot aluminum. This can potentially leave burns where the metal lands, ringed by plastic burned into the skin.”

And when you’re not using your homemade metal foundry, it even doubles as a home decor planter!

If you want to learn how to make a soup can forge, here’s a cool video, which inspired this awesome metal foundry.

Very cool homemade DIY tech. However, ALWAYS Be Safe!

***

Credits: Subscribe to King of Random for new videos every 5 days! http://bit.ly/TKoRSubscribe

***

WARNING: Besides being extremely HOT and posing a severe burn risk if not handled properly, molten aluminum also emits toxic fumes. Wear a respirator that is designed for these kind of fumes. The CDC has good info on aluminum here: http://www.atsdr.cdc.gov/phs/phs.asp?id=1076&tid=34 Use proper safety protocol when handling molten metals. If you don’t know what you’re doing, don’t do it.

|

Like this article? Subscribe to our newsletter to get more great content and updates sent to your inbox! |

Aluminum Can Melting | purathrive reviews

Tuesday 23rd of August 2016

[…] Melting Aluminum Cans With $20 Homemade Mini Metal Crucible – Let’s melt some metal! The King Of Random has done it again by building a homemade metal foundry with a steel crucible that will melt aluminum cans with over 1000 degrees of heat provided by regular old charcoal and a hair dryer. Grant … […]

Prepper News Watch for January 8, 2015 | The Preparedness Podcast

Thursday 8th of January 2015

[…] Melting Aluminum Cans With $20 Homemade Mini Metal Crucible […]